Products

Ball Valves (Control & On-Off)

Non contact top entry ball valve

Gate Valves

Globe Valves

Check Valves

Axial Nozzle Check Valve

Butterfly (on-off and control)

Globe Control Cage Guided

Axial Flow Valves (on-off and control)

Choke Valves

HIPPS

Actuators

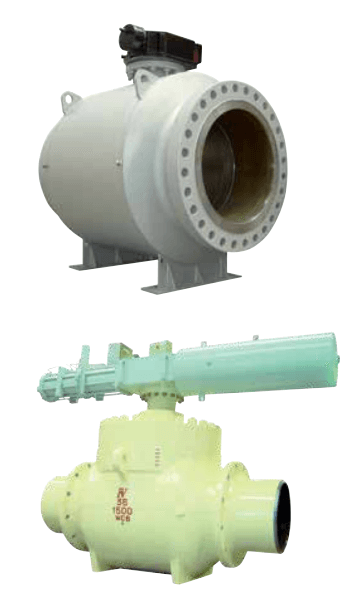

Ball Valves (Control & On-Off)

BALL VALVES

Standards and Specifications

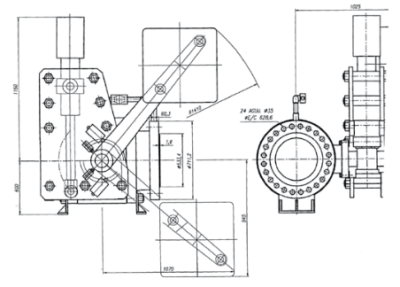

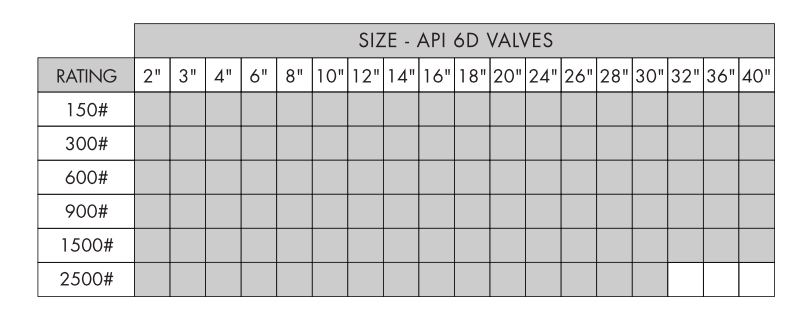

Ball valves are mainly designed to conform API 6D (Specification for pipeline valves) and ANSI B16.34 (Valves Flanged, Threaded and Welding End) or API 6A (Specification for Wellhead and Christmas Tree Equipment) in case of upstream applications. Other related standards such as ANSI B16.5 (Pipe Flanges and Flanged Fittings), ANSI B16.25 (Buttwelding Ends), ANSI B16.10 (Face to Face and End-to-End Dimensions of Valves) are also used for the design of ball valves. Also our ball valves are designed to meet FIRE SAFE requirements to BS6755, API 6FA and API 607. Final testing is done to conform API 598 (Valve Inspection and Testing) MSS-SP-61 (Pressure Testing of Steel Valves) API 6D (Specification for Pipeline Valves) or API 6A (Specification for Wellhead and Christmas Tree Equipment) requirements. Materials are selected mainly to ASTM standards and when sour service is specified to meet NACE MR-01-75 (Sulfide Stress Cracking resistant Metallic Materials for Oilfield Equipment).Gas-Over-Oil Actuated Valves

This valve is used in gas pipelines and the actuator is powered directly from the line gas pressure. Valves actuator may be provided with line break detection system which closes the valve in case that the gradient of pressure drop in the line is greater than a preset value.Emergency Assisted Ball Valves

This valve is intended for protection of turbine/pump in hydroelectric power stations. Valve is assembled in horizontal position and provided with a hydraulic piston to open the valve. In case of reverse flow which may damage the turbine/pump, this is detected by a pressure transducer which sends a signal to the valve releasing the pressure in the hydraulic piston and allowing the valve counterweight to close the valve in few seconds avoiding line counterflow to reach the turbine/pump.Fully Welded Ball Valves

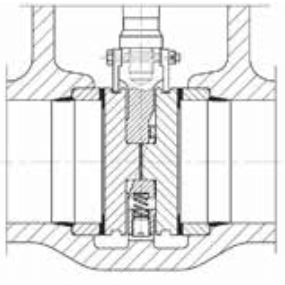

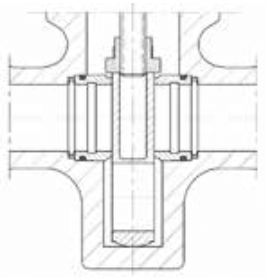

ully Welded ball valves are available for those cases when leakage throughout atmosphere must be absolutely avoided such as in gas transmission pipelines. Valve is built in three pieces fully welded constructions.Top-entry Ball Valves

The Top-entry valve types have a major application when a frequent maintenance must be carried out and the valve can not be easily removed from the pipe. In this valve model, all the internals can be easily dismounted by loosening the bonnet of the valve and removing the ball, the seat-holders and the shaft. When mounting the valve again, the seat-holders have a system to regulate the compression of these to the ball.In-Line Serviceable Ball valves

For sizes up to 6”, this type of valve can be used giving the same possibility of maintenance as top entry ball valve but being a construction much more economical.API6A Ball valves

For upstream applications, three pieces side entry ball valve is used in accordance with the requirements of API 6A. Valve classes from class 2000 to class 20000 In sizes from 2-1/16” to 7-1/16” are available. Material selection is done in full compliance with API 6A requirements. Valve designs are available to meet Pressure Product Requirement levels PSL-1, PSL-2, PSL-3 / PSL-3G and PSL-4.

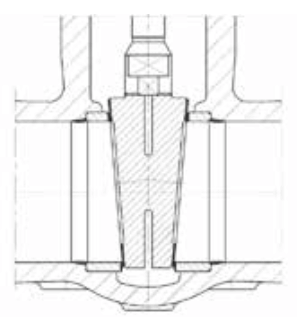

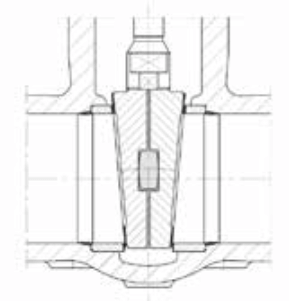

Non contact top entry ball valve

Non contact top entry ball valve

Description

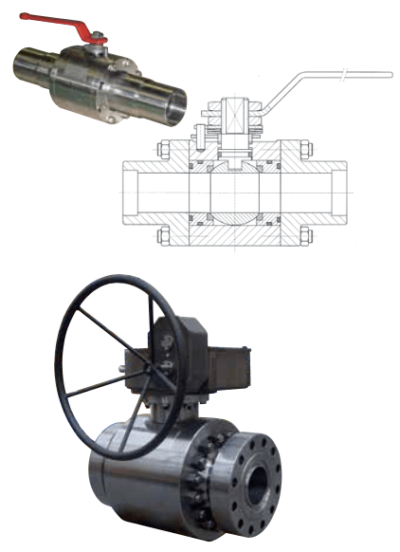

Ringo Válvulas NCBV non contact top entry ball valves series are designed and produced according to API 6D/ ISO 14313, API 6A, API 6DSS / ISO 14723, BS5351, ASME B16.34 and other international standards as well as customer specifications on request.

These valves are built of a single piece body with a bolted bonnet. This design is a robust construction that provides a good performance, smooth operation, minimum pressure loss, high Cv values and also allows bonnet disassembly on site to perform inspection, maintenance or repair without removing the valve body from the pipeline.

The Top-entry valve types have a major application when a frequent maintenance must be carried out and the valve cannot be easily removed from the pipe. In this valve series, all the internals can be easily dismounted by loosening the bonnet of the valve and removing the ball, the seat-holder and the shaft.

Valves can be supplied manual operated or with any kind of operator for ESDV, SDV, BDV, MOV, GOV or LBV functions (electric drive, pneumatic, hydraulic, electro hydraulic or pneumo-hydraulic actuator).

Valve Size-pressure rating

Design characteristics range

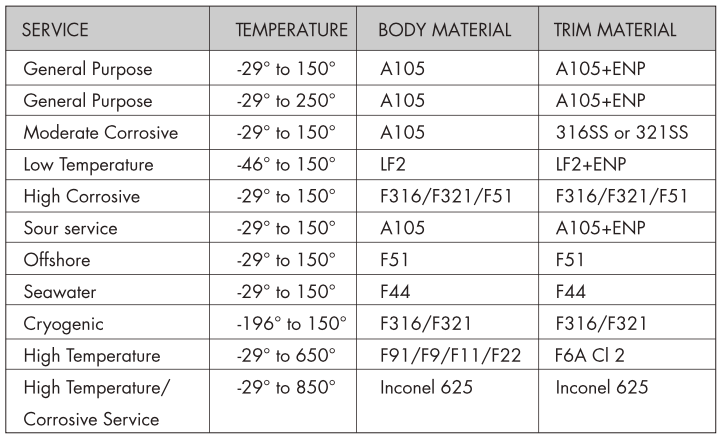

Working Principle

NCBV Ball Valves have a ball which is supported by a bottom trunnion. When the bore is oriented to the pipeline direction, valve is in the open position, allowing the fluid pass through. The stem start moving down and due to the channels machined on it in spiral it turns 90o forcing the ball to turn the same. Then the channels are machined straight and the stem cannot turn moving only down.

In this situation due to an angled surface, the stem pushes the ball that pivots on the bottom trunnion and contacts the seat. Ball only contacts the seat in this position then there is not friction during the rest of the stroke.

Ringo Válvulas can supply NCBV ball valves in two configurations:

- Full Bore: Size of the trim is the same of the pipeline. In this case valve is suitable for pigging. Special large bores for particular PIG dimensions are available on request.

- Reduced bore: Size of the trim is smaller than the pipeline size. Number of reduced sizes is according to API 6D unless otherwise is agreed for the particular job.

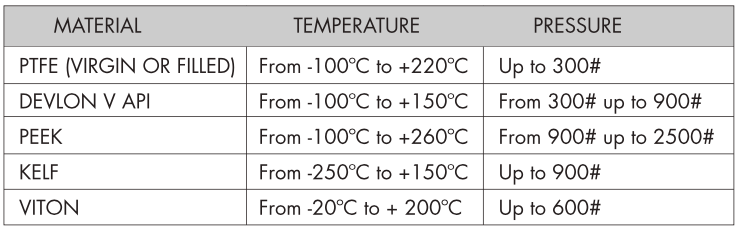

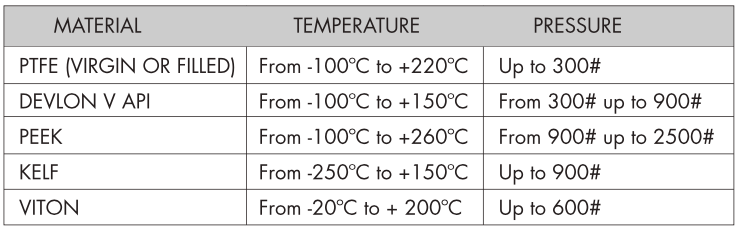

A) Soft seats

The seat assembly consists in an outer metallic seat carrier with a soft seat insert. The soft insert is located into a groove in the metallic seat carrier.

B) Metal seats:

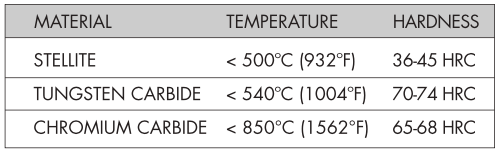

When there is presence of solid particles in the fluid that could damage the soft seat insert or for either high temperature services or high pressures, where soft insert cannot withstand it. Seats consist of a metallic ring where surface in contact with the ball is hardfaced with Tungsten Carbide, Chromium Carbide, Stellite etc., achieving a hardness up to 74 HRC (Tungsten Carbide). This makes the design long durable and reliable and able to achieve classes C & D leakage class metal seated.

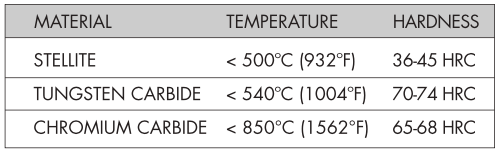

Materials

Ringo Válvulas ball valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure and temperature. Valves can be supplied either forged or casted based on customer specifications. Following materials are under the scope of supply of Ringo:- Carbon Steel valves

- Low temperature carbon steel

- High temperature alloy steel

- Stainless Steel Valves

- Super Austenitic Stainless Steel

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Ni Alloy

- Titanium

- Aluminum bronze

Actuation

Ringo Válvulas covers all the possibilities regarding ball valves actuation. Valves can be supplied with the following operator types:- Manual: handwheel, gear operated

- Electrical actuator

- Pneumatic actuator

- Gas Over Oil actuator

- Direct Gas actuator

- Hydraulic actuator

- Electro-hydraulic actuator

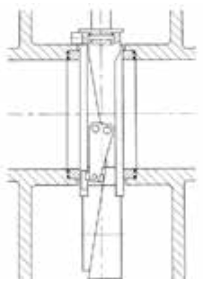

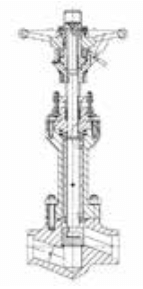

Gate Valves

Gate Valves

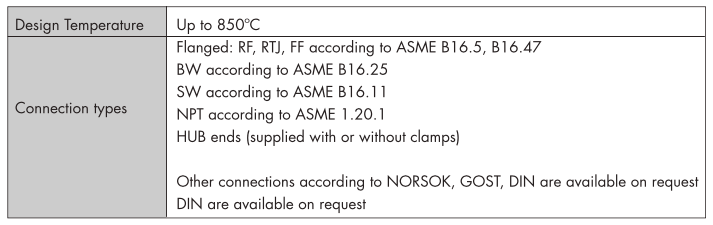

Gate Valves Features

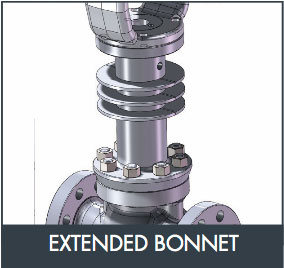

Optional features:

- Lantern ring

- Equalizer

- Locking device

- Stem extension

- Leak-Off & Packing Expulsor

- Low emission packing

- Non rising stem

- Bellows seal gate

Manual / MOV / AOV / HOV / Electrohydraulic

Types:Wedge Gate/ through conduit / Double expanding

Construction:Bolted bonnet / Pressure seal

Disc type:Solid / Flexible/ Split /Parallel slide

Standard features:

Ringo Válvulas gate valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure and temperature. Valves can be supplied either forged or casted based on customer specifications. Following materials are under the scope of supply of Ringo:

OS&Y / Backseat

Materials:Ringo Válvulas gate valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure and temperature. Valves can be supplied either forged or casted based on customer specifications. Following materials are under the scope of supply of Ringo:

- Carbon Steel valves

- Low temperature carbon steel

- High temperature alloy steel

- Stainless Steel Valves

- Super Austenitic Stainless Steel

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Ni Alloy

- Titanium

- Aluminum bronze

Wedge Gate Valves

Solid Wedge Design:

The wedge is made in one solid piece being the downstream side the one which seals the valve when upstream pressure push the wedge againts te downstream seat.

The wedge is made in one solid piece being the downstream side the one which seals the valve when upstream pressure push the wedge againts te downstream seat.

Flexible Wedge Design

The wedge has a machined groove in its central part providing flexibility at the disc.

The wedge has a machined groove in its central part providing flexibility at the disc.

Split Wedge Design

The wedge is made in two separate parts providing high ability to seal. This is recommended when high thermal or mechanical deformations are expected due to working conditions.

The wedge is made in two separate parts providing high ability to seal. This is recommended when high thermal or mechanical deformations are expected due to working conditions.

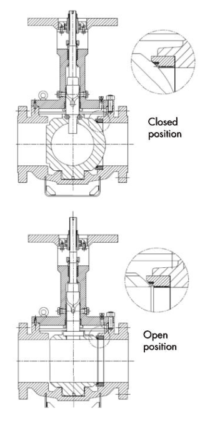

Parallel Gate Valves

Parallel Slide Gate Valves

For those applications when large temperature variations are expected or fast shutt-off is required, this is the most ideal design. The seats are parallel and the disc has no contact with the seats during the stroke of the valve. Only at the end of the stroke the disc mechanism ensures the contact between seats and disc.

For those applications when large temperature variations are expected or fast shutt-off is required, this is the most ideal design. The seats are parallel and the disc has no contact with the seats during the stroke of the valve. Only at the end of the stroke the disc mechanism ensures the contact between seats and disc.

Through Conduit

When full port gate valve is required or double block and bleed valve is mandatory this design must be used. Through conduit gate valves are designed to API 6D or API 6A. These valves are pigeable and normally used for oil and gas application.

When full port gate valve is required or double block and bleed valve is mandatory this design must be used. Through conduit gate valves are designed to API 6D or API 6A. These valves are pigeable and normally used for oil and gas application.

Double Expanding Gate

Metal to Metal seated, double block and bleed are available toAPI6D&API6A.

Metal to Metal seated, double block and bleed are available toAPI6D&API6A.

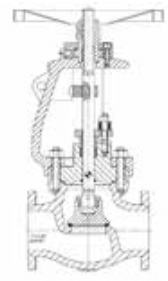

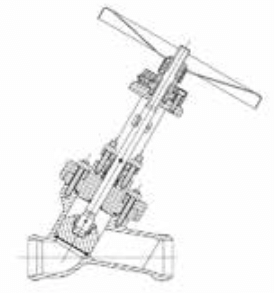

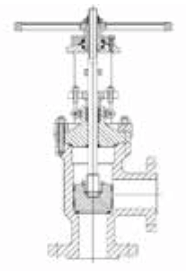

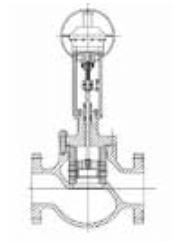

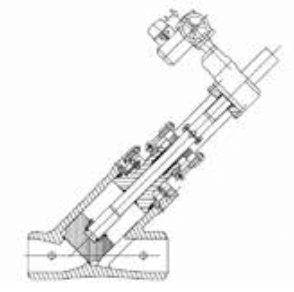

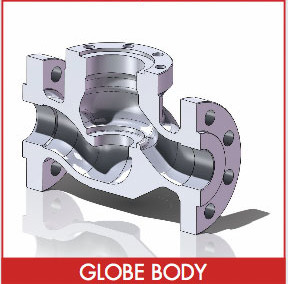

Globe Valves

Globe Valves

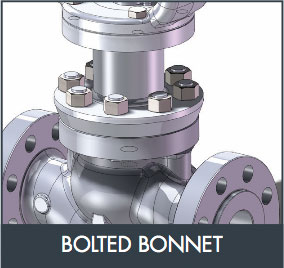

Globe Valves Features

Types:

Ringo can supplied any of the materials mentioned above to fulfill any additional requirement included in customer specifications.

Ringo can supplied any of the materials mentioned above to fulfill any additional requirement included in customer specifications.

- Straight pattern / Y pattern / Angle pattern / 3-Way / Stop check

- Bolted bonnet / Pressure seal

- Flat / Parabolic / Needle

- OS&Y / Backseat

- Lantern ring

- Leak-Off & Packing Expulsor

- Locking device

- Stem extension

- Low emission packing

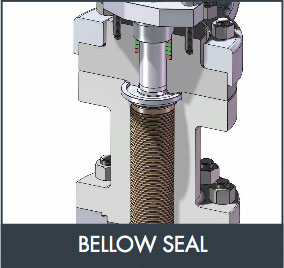

- Bellows seal

- Zero stem leakage

Operation:

Ringo Válvulas globe valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure and temperature. Valves can be supplied either forged or casted based on customer specifications. Following materials are under the scope of supply of Ringo:

- Manual / MOV / AOV / HOV / Electrohydraulic

Ringo Válvulas globe valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure and temperature. Valves can be supplied either forged or casted based on customer specifications. Following materials are under the scope of supply of Ringo:

- Carbon Steel valves

- Low temperature carbon steel

- High temperature alloy steel

- Stainless Steel Valves

- Super Austenitic Stainless Steel

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Ni Alloy

- Titanium

- Aluminum bronze

Ringo can supplied any of the materials mentioned above to fulfill any additional requirement included in customer specifications.

Ringo can supplied any of the materials mentioned above to fulfill any additional requirement included in customer specifications.Globe Valves Configurations

Straight Pattern

This is the most commonly used design (standard T-Pattern), providing large pressure drop across the valve.

This is the most commonly used design (standard T-Pattern), providing large pressure drop across the valve.

Y-Pattern

When lower pressure drop across the valve is required Y-Pattern is recom-mended.

When lower pressure drop across the valve is required Y-Pattern is recom-mended.

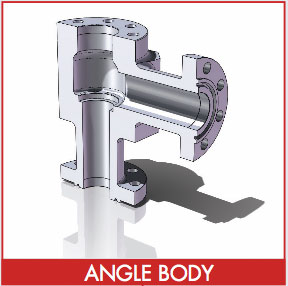

Angle (90o)-Pattern

This design is used when two perpen-dicular pipes must be connected.

This design is used when two perpen-dicular pipes must be connected.

Cage Guided

In those cases when valve is intended for control or throttling service, cage guided design is required. There are different types of cages and trims designed to provide different valve characteristics and Cv-values.

In those cases when valve is intended for control or throttling service, cage guided design is required. There are different types of cages and trims designed to provide different valve characteristics and Cv-values.

Special Globe Valves

Choke Valves

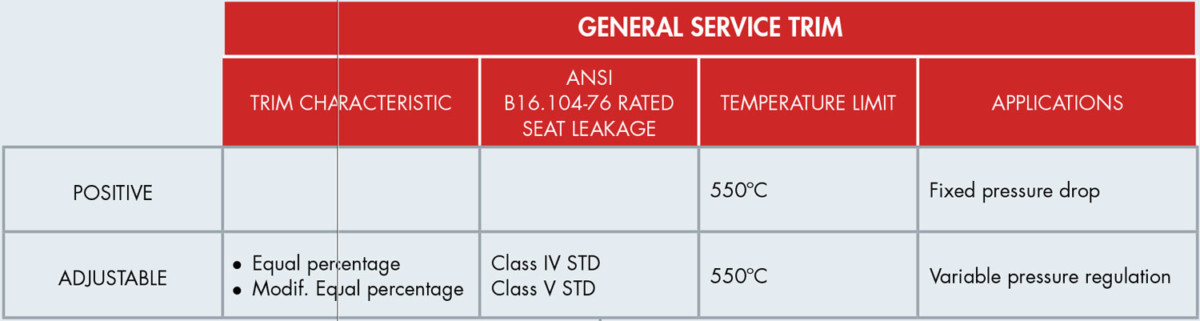

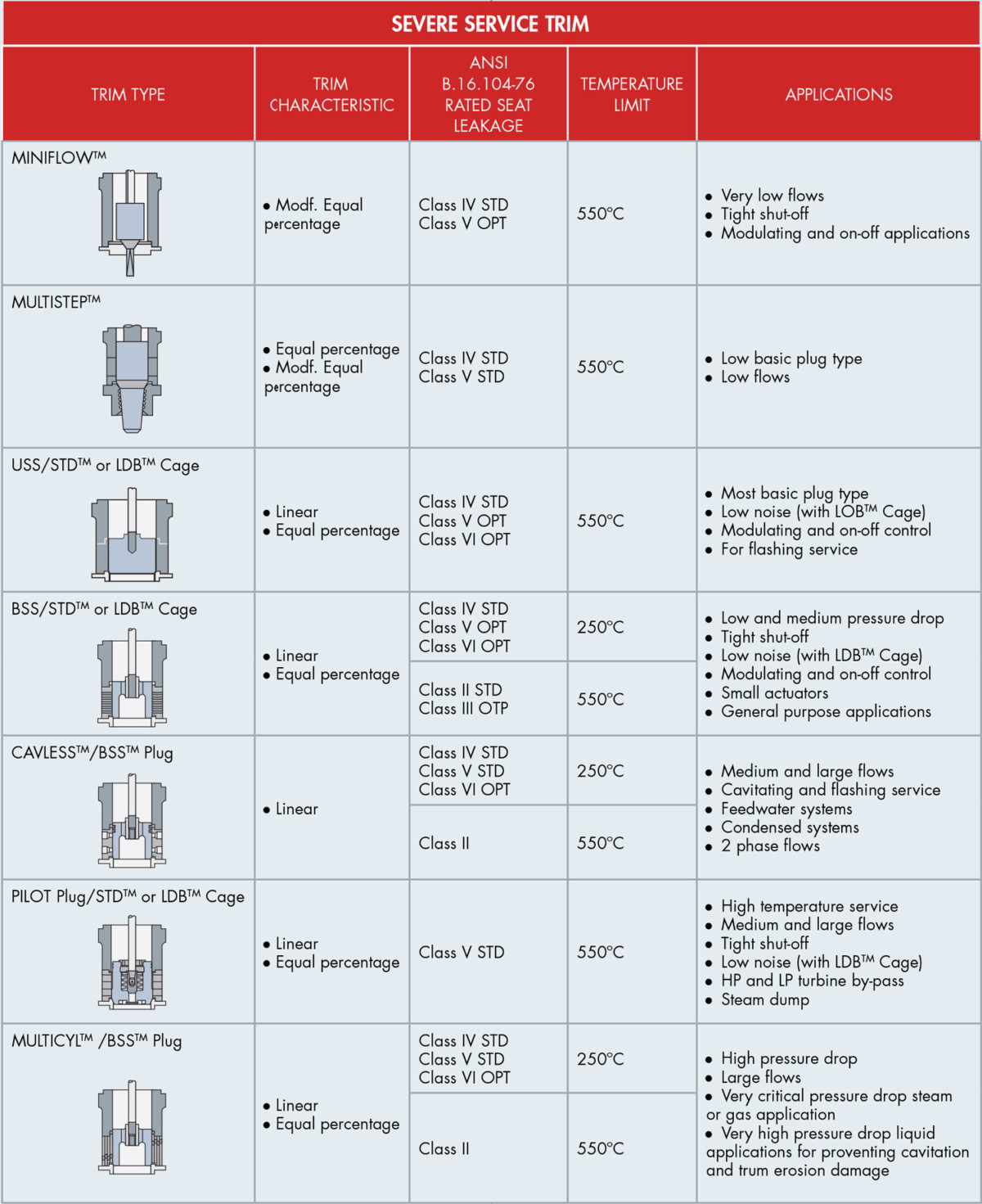

For API 6A applications choke valves, both positive and adjustable are available. Choke valves are specifically design for service conditions providing different types of beans for positive chokes (including ceramic materials, tungstem carbide and hardened mar-tensitic steels) as well as different configurations of seats, cages and discs for adjustable chokes.

For API 6A applications choke valves, both positive and adjustable are available. Choke valves are specifically design for service conditions providing different types of beans for positive chokes (including ceramic materials, tungstem carbide and hardened mar-tensitic steels) as well as different configurations of seats, cages and discs for adjustable chokes.

Stop Check Valves

This design is a combination between globe valve and check valve. When valve is open, the stem is in open position the valve operates like a piston check valve, disc is moved by the fluid-media. However when valve has to be closed the stem goes down againts the disc ensuring dhut-off of the valve.

This design is a combination between globe valve and check valve. When valve is open, the stem is in open position the valve operates like a piston check valve, disc is moved by the fluid-media. However when valve has to be closed the stem goes down againts the disc ensuring dhut-off of the valve.

Bellows-Sealed Valves (Zero Stem Leakage)

For those applications when emissions to the atmosphere are strictly forbidden, valve is provided with metallic bellows which ensures no leakage through the stem packing to the atmosphere.

For those applications when emissions to the atmosphere are strictly forbidden, valve is provided with metallic bellows which ensures no leakage through the stem packing to the atmosphere.

Control Valves

RV offers a wide range of control valves for the most severe appli-cations. In those cases when valve is intended for control or throttling service, cage guided design is required. There are different types of cages and trims designed to provide different valve characteristics and Cv-values.

RV offers a wide range of control valves for the most severe appli-cations. In those cases when valve is intended for control or throttling service, cage guided design is required. There are different types of cages and trims designed to provide different valve characteristics and Cv-values.

Globe Valves Manufacturing Range

| Standars | Sizes |

| ANSI B16.34 BS 1873 | 1/2”-48” 150#-300# 1/2”-42” 600# 1/2”-36” 900# 1/2”-30” 1500# 1/2”-24” 2500# 1/2”-12” 4500# |

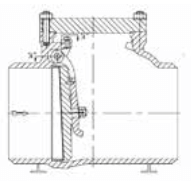

Check Valves

Check Valves

Check Valves Features

Types:

- Swing check / Dual plate / Tilting Disc / Piston check / Ball check / Single

- Disc / Axial check

- Bolted bonnet / Pressure seal

- Wafer / Lug / Double flanged

- Position indicator

- Locking devic

- Emergency assisted valves

- Dumpered valves

Materials:

Ringo Válvulas Check valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure and temperature. Valves can be supplied either forged or casted based on customer specifications. Following materials are under the scope of supply of Ringo:

Ringo Válvulas Check valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure and temperature. Valves can be supplied either forged or casted based on customer specifications. Following materials are under the scope of supply of Ringo:

- Carbon Steel valves

- Low temperature carbon steel

- High temperature alloy steel

- Stainless Steel Valves

- Super Austenitic Stainless Steel

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Ni Alloy

- Titanium

- Aluminum bronze

Ringo can supplied any of the materials mentioned above to fulfill any additional requirement included in customer specifications.

Ringo can supplied any of the materials mentioned above to fulfill any additional requirement included in customer specifications.Globe Valves Configurations

Swing Check Valves

Valve disc is provided with antirota-tions pin. Full opening swing check valves to API 6D or API 6A suitable for pig passage are also available.

Valve disc is provided with antirota-tions pin. Full opening swing check valves to API 6D or API 6A suitable for pig passage are also available.

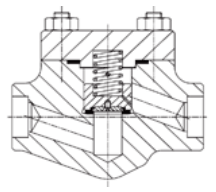

Piston Check Valves

Normally upto sizes 2”, (larger sizes are also available) both T-Pattern and Y-Pattern are available.

Normally upto sizes 2”, (larger sizes are also available) both T-Pattern and Y-Pattern are available.

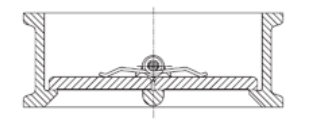

Dual Plate Check Valves

Valves provided with double disc and spring. They are available with metal to metal seats and soft seats. This design reduces substantially the weight of the valve as well as the face to face dimension.

Valves provided with double disc and spring. They are available with metal to metal seats and soft seats. This design reduces substantially the weight of the valve as well as the face to face dimension.

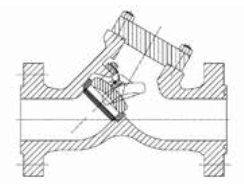

Tilting Disc Check Valves

When the check valve must be operated by a very small pressure drop this design is used. Valve disc is balanced in such a way that very small variations of pressure open/close the valve. This reduces substantially the pressure drop across the valve.

When the check valve must be operated by a very small pressure drop this design is used. Valve disc is balanced in such a way that very small variations of pressure open/close the valve. This reduces substantially the pressure drop across the valve.

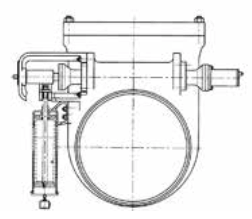

Emergency Assisted Check Valves

Used in the turbine steam extractions of power plants. Valve is provided with a pneumatic piston and solenoid valve in such a way that when a closing signal is received in the solenoid valve the air in the pneumatic piston is released starting the closing stroke of valve disc and ensuring fast valve closing by fluid-media.

Used in the turbine steam extractions of power plants. Valve is provided with a pneumatic piston and solenoid valve in such a way that when a closing signal is received in the solenoid valve the air in the pneumatic piston is released starting the closing stroke of valve disc and ensuring fast valve closing by fluid-media.

Testable Check Valves

In those cases when indication of check valve position is required the valve is provided with a position indicator and limit switches. Also a operating lever is available in case proper rotation of hinge shaft must be checked.

In those cases when indication of check valve position is required the valve is provided with a position indicator and limit switches. Also a operating lever is available in case proper rotation of hinge shaft must be checked.

Normally used in the outlet of large size pumps or inlet of hydro power plant turbines. Valve can operate like a butterfly valve but also like a check valve by fluid-media.

Check Valves Manufacturing Range

| Standars | Sizes |

| ANSI B16.34 API 6D BS 1868 | 1/2”-72” 150# 1/2”-64” 300# 1/2”-56” 600# 1/2”-48” 900# 1/2”-36” 1500# 1/2”-30” 2500# 1/2”-24” 4500# |

| API 6A | 2-1/16”- 11” 2000 psi 2-1/16”- 11” 3000 psi 2-1/16”- 11” 5000 psi 1-13/16”- 7 1/16” 10000 psi 1-13/16”- 4 1/16” 15000 psi 1-13/16”- 3-1/16” 20000 psi |

Axial Nozzle Check Valve

Axial Nozzle Check Valve

Description

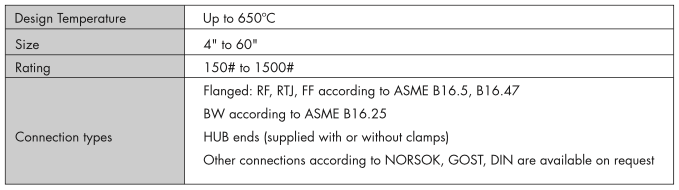

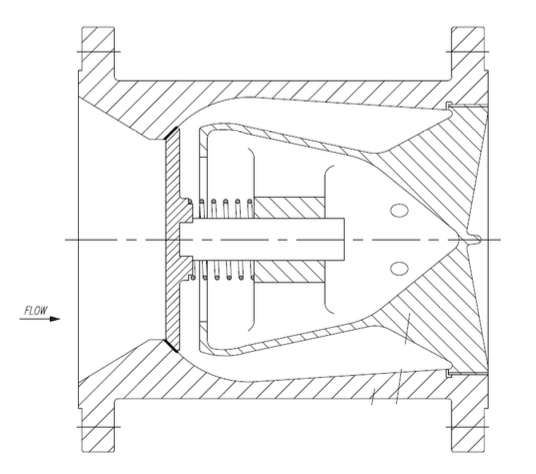

Check valves are used in numerous installations for various purposes and it is always a challenge for the planning engineer to find suitable return flow preventers. Often it does not become evident until a plant is being run on test that the selected non return valves slam heavily and produce high pressure peaks which exceed the permissible pressure to such an extent that the installation and the surroundings are endangered. A further important factor in the present and future is economy (the savings of energy). A feature of the Samson Ringo Axial Flow Check Valves is its inherent non slam characteristic. This is achieved because the valve reacts so quickly to flow changes. This causes that the valve change the point of closure without letting any possible reverse flow. This avoid water hammer effect for liquid service and ensures no chance of reverse flow into the compressor for gas service. Additional benefits of the Samson Ringo Axial Flow Check Valves design are:- Low pressure drop and turbulence due to the streamlined flow path.

- Extremely long service life because the moving parts are not subjected to the shocks associated with typical asymmetric valve designs.

- The valve has no soft parts to wear, cause misalignment, or need replacing.

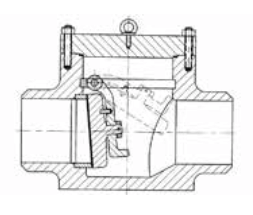

Design characteristics range

Design options

Samson Ringo offers to its customers two different design of the Axial Flow Check Valves:Solid disc design

This is the design commonly used for valves below 12″.

This is the design commonly used for valves below 12″.

Ring disc design

In this design, typically used for sizes 14″ and above, main advantages are the low friction, quick response and low pressure loss.

In this design, typically used for sizes 14″ and above, main advantages are the low friction, quick response and low pressure loss.

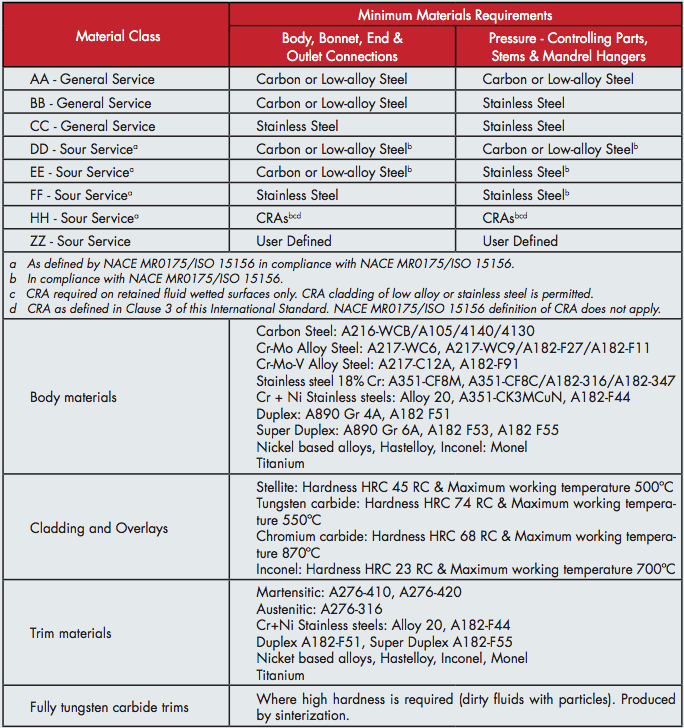

Materials

Body

- Carbon Steel : A216-WCB/WCC.

- Cr-Mo Alloy Steel : A217-WC6, A217-WC9.

- Cr-Mo-V Alloy Steel : A217-C12A.

- Nickel based alloys, Hastelloy, Inconel; Monel. Titanium.

Trim

- Martensitic : A217 Gr, CA15.

- Austenitic: A351 Gr, CF8/CF8M.

- Stainless steel 18% Cr: A351-CF8M, A351-CF8C

- Cr + Ni Stainless steels: Alloy 20, A351-CK3MCuN

- Duplex A890-Gr. 4A, Super Duplex A890-Gr. 6A

- Nickel based alloys, Hastelloy, Inconel; Monel Titanium.

Cladding and overlays

- Stellite: Hardness HRC 45 RC & Maximum working temperature 500°C.

- Tungsten carbide: Hardness HRC 74 RC & Maximum working temperature 550°C.

Butterfly (on-off and control)

Butterfly (on-off and control)

Butterfly Valves (On-Off & Control) Features

Types:

- Concentric

- Double eccentric

- Triple eccentric

Seats:

- Soft / Metal Seated

Construction:

- Wafer / Lug / Double flanged

Operation:

- Manual / MOV / AOV / HOV / Electrohydraulic

Materials:

Ringo Válvulas Butterfly valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure and temperature. Valves can be supplied either forged or casted based on customer specifications. Following materials are under the scope of supply of Ringo:

Ringo Válvulas Butterfly valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure and temperature. Valves can be supplied either forged or casted based on customer specifications. Following materials are under the scope of supply of Ringo:

- Carbon Steel valves

- Low temperature carbon steel

- High temperature alloy steel

- Stainless Steel Valves

- Super Austenitic Stainless Steel

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Ni Alloy

- Titanium

- Aluminum bronze

Ringo can supplied any of the materials mentioned above to fulfill any additional requirement included in customer specifications

Ringo can supplied any of the materials mentioned above to fulfill any additional requirement included in customer specificationsButterfly Valves (On-Off & Control) Manufacturing Range (On-Off и управление)

| Standars | Sizes |

| AWWA C-504 | 40”-120” CLASS 25A-250A |

| BS – 3952 | 3”-40” ANSI 600# |

Globe Control Cage Guided

Globe Control Cage Guided

Globe Control Cage Guided Features

Types:

- Straight pattern / Y pattern / Angle / 3-Way / Bellows seal

- Bolted bonnet / Pressure seal

- Mini flow / Multistep / USS STD / USS LDB

- BSS STD / BSS LDB

- Pilot / Multicylinder / Cascade

- OS&Y / Backseat

- Lantern ring

- Leak-Off & Packing Expulsor

- Double packing

- Stem extension

- Low emission packing

- Bellows sealed control globe

- Pneumatic diaphragm / Pneumatic piston / Hydraulic piston / Electric

- Electrohydraulic

Materials:

Ringo Válvulas Globe Control valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure and temperature. Valves can be supplied either forged or casted based on customer specifications. Following materials are under the scope of supply of Ringo:

Ringo Válvulas Globe Control valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure and temperature. Valves can be supplied either forged or casted based on customer specifications. Following materials are under the scope of supply of Ringo:

- Carbon Steel valves

- Low temperature carbon steel

- High temperature alloy steel

- Stainless Steel Valves

- Super Austenitic Stainless Steel

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Ni Alloy

- Titanium

- Aluminum bronze

Ringo can supplied any of the materials mentioned above to fulfill any additional requirement included in customer specifications.

Ringo can supplied any of the materials mentioned above to fulfill any additional requirement included in customer specifications.Globe Control Cage Guided Manufacturing Range

| Standars | Sizes |

| ASME B16.34 | 1/2”-36” 150#-300# 1/2”-30” 600# 1/2”-28” 900 1/2”-24”1500# 1/2”-20” 2500# 1/2”-12” 4500# |

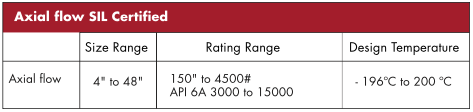

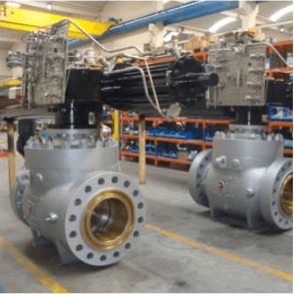

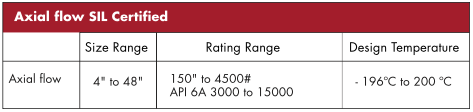

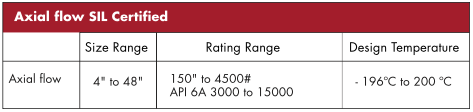

Axial Flow Valves (on-off and control)

Axial Flow Valves

Advantages of Samson Ringo Axial Flow Valve

- Largest Cv value, combined with high rangeability.

- Cage guided balanced plug for smooth operation.

- Variety of cage designs to handle gas and liquid critical applications.

- Drive mechanism’s multiplier effect give maximum thrust when it is needed.

- Unique Rotary-to-Linear drive mechanism simplifies actuator requirements.

- Standard electric or pneumatic 90o actuator with standard positioner can be used. – Smooth, precise control.

- Reduced friction.

- Backlash free.

- Environmentally safe: Low emissions due to rotating shaft.

- Drive mechanism is not affected by dirty fluids.

- Reduced force requirements by more than half.

- Более высокая пропускная способность на рынке при тех же размерах, более 30 % в клапанах on-off.

Ringo Válvulas Axial Flow valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure and temperature. Valves can be supplied either forged or casted based on customer specifications. Following materials are under the scope of supply of Ringo:

- Carbon Steel valves

- Low temperature carbon steel

- High temperature alloy steel

- Stainless Steel Valves

- Super Austenitic Stainless Steel

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Ni Alloy

- Titanium

- Aluminum bronze

Operation:

- Manual

- Pneumatic

- Hydraulic

- Electric

- Electrohydraulic

- One piece body

- STD / LDB / DobDrill / DobCage

Body design

A streamlined body with constant sectional area, offers a very reduced coefficient resistance and gives larger Cv values for the same sizes. Fluid is channeled into an annular path between the inner and outer bodies until it reaches the characterized cage. Smooth changes in flow direction and no turbulences contribute to lower noise levels. The high capacity, combined with the large rangeability, make our axial valve to be acknowledged as the ideal design to control over the full range of process conditions with a single valve. As an option extended body neck is offered for cryogenic operations. Low emission is guaranteed by the O-ring seals combined with back-up packing. Distance between flanges is in accordance with ISA 75.03 when data are available or API 6D for larger sizes. Actuator flanges are machined according to ISO 5211 or other standards. All types of quarter turn actuator are easily mounted. Casted range from 4” to 48” and ratings from 150# to 2500#. Forged three pieces for sizes below 4” and pressures above 2500#. Constant flow passage area ensures the maximum possible capacity for on-off application due to reduction of the K resistance coefficient.Trim design

Advantages of stem guided plug:- Can be used for on-off application without cage in order to achieve high capacity.

- Control is performed by hole pattern.

- Possibility of using multi-cage designs to perform multistage pressure reduction of high noise/cavitation conditions.

- Availability of balanced plugs, to reduce the required actuator torque.

- The inner chamber, wich includes the transmission system is pressure balanced, due to that no fluid movement is occurring inside this area.

- Bearings of transmission mechanism are protected against particles by a cover.

Drive Mechanism Design

- Multiplier effect reduces force torque and actuator size.

- It is not affected by dirt, impurities or fluid conditions.

- No gap, low friction bushings in crank and rod junctions assure a smooth, no backlash movement of the plug.

- The drive mechanism is designed to multiply the actuator force applied to the plug when it is needed. This feature makes it possible to select lower torque, smaller size actuator and reduce operating times.

- КрAdditionally it improves the valve inherent rangeability. At the beginning of the opening a large angle of rotation means a small change in the stroke of the plug. Good for start-up conditions with small cv values.

- All together it combines to give smooth, accurate fast operation of the valve with smaller size actuator and enhanced ran- geability.

- Low friction sealing of rotating shaft.

- Low friction bearings in the transmission of movement, from shaft to plug stem.

- Plug, guided by the stem is fully balanced in both axial and radial directions and gives no friction to cage.

- Multiplier effect that reduces the required actuation force.

- Maximum force is delivered when it is most needed at opening and closing.

- All the above combine to greatly reduce the torque, the size of the actuator and the operating time.

Choke Valves

Choke Valves

Choke Valves Features

Ringo is API 6A certi ed for production and testing of chokes according to all Product Speci cation Levels: PSL1, PSL2, PSL3, PSL3G and PSL4 as well as for the two different Product Requirements: PR1 and PR2, depending on services and customer requirements. In addition, our chokes can be design and produce according to other different standards on request, such as ASME B16.34 or GOST.

Body

Bonnet

Trim Service

Actuators

HIPPS

HIPPS

SAMSON RINGO HIPPS IS PROVIDED

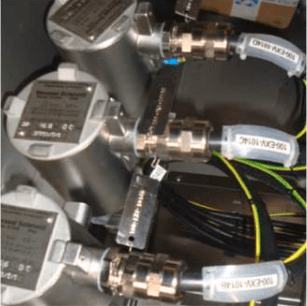

Initiators (pressure transmitters)

HIPPS are typically supplied with three pressure transmitters that monitor the pressure in the line and provide the information to the next element. This three elements can be selected from the same supplier or three different ones; supplying the pressure transmitters of three different brand avoid what it is call a “common fail”, for instance a quality problem in a lot of Pressure Transmitters produced by the same manufacturer that could affect to the proper performance of the HIPPS. HIPPS is designed to be able work only with two Pressure Transmitters for a while. This is to allow to make some checking or to replace any of them with the HIPPS under operation. In such case, system is working in “degraded mode” and logic solver receives that information.

Logic Solvers

Logic solver is the device in charge of processing the input signals received from the initiators and it is configured to send the signal to operate the final elements, when the received input is above the preconfigured pressure value. Ringo can supply HIPPS with different types of logic solvers:

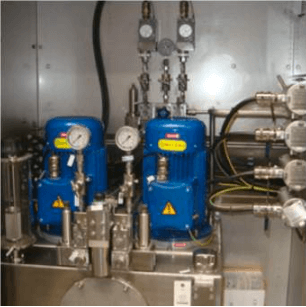

Final Elements

Final elements have the function of isolating the downstream part of the installation from the overpressure. Typically, final elements consist of two valves with their related actuators installed in serial to be closed when the signal is received from the logic solver. Actuators may be pneumatic or hydraulic and are supplied with their own control panel, including the solenoid valves to govern their operation. Actuators are sized to provide a very fast operation time (less than 2 seconds). Samson Ringo offers two type of valves for HIPPS: Ball and Axial.

HIPPS are typically supplied with three pressure transmitters that monitor the pressure in the line and provide the information to the next element. This three elements can be selected from the same supplier or three different ones; supplying the pressure transmitters of three different brand avoid what it is call a “common fail”, for instance a quality problem in a lot of Pressure Transmitters produced by the same manufacturer that could affect to the proper performance of the HIPPS. HIPPS is designed to be able work only with two Pressure Transmitters for a while. This is to allow to make some checking or to replace any of them with the HIPPS under operation. In such case, system is working in “degraded mode” and logic solver receives that information.

Logic Solvers

Logic solver is the device in charge of processing the input signals received from the initiators and it is configured to send the signal to operate the final elements, when the received input is above the preconfigured pressure value. Ringo can supply HIPPS with different types of logic solvers:

- Central Processing Unit (CPU): software can be programmed to configure the response based on the inlet signals. This type is certified up to SIL 3.

- Solid State Logic (SSL), with a configuration of intelligent cards. This type cannot be programmed but can be certified up to SIL 4.

- Mod bus, OPC, Profibus, Send and Receive TCP & HART.

Final Elements

Final elements have the function of isolating the downstream part of the installation from the overpressure. Typically, final elements consist of two valves with their related actuators installed in serial to be closed when the signal is received from the logic solver. Actuators may be pneumatic or hydraulic and are supplied with their own control panel, including the solenoid valves to govern their operation. Actuators are sized to provide a very fast operation time (less than 2 seconds). Samson Ringo offers two type of valves for HIPPS: Ball and Axial.

Valves

Ball Valves

Ringo Válvulas offer a full range of trunnion mounted ball valves designed and produced according to API 6D/ ISO 14 API 6DSS / ISO 14723, BS5351, ASME B16.34 and other international standards as well as customer specifications on with all the possible configuration:

Standard features

- Bidirectional flow.

- Trunnion Design for Low Torque Operation.

- Soft seated or Metal Seated construction.

- Automatic Cavity Pressure Relief.

- Anti Blow-Out Stem.

- Grease Fittings.

- Drain and vent.

- Antistatic Device.

- Fire Safe Design & Certified API 6FA, API607 and BS6755.

Optional features

- Double piston effect.

- Double Block-Bleed.

- Locking Device.

- Flanged grease fittings, vents and drains.

- Stem extension.

- Low emission packing.

- Live loaded packing.

- Lip Seals.

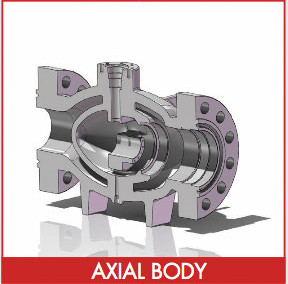

Axial Valves

Design:

A stream lined body with constant sectional area, offers a very reduced coefficient resistance and gives larger Cv values for the same sizes.

Fluid is channeled into an annular path between the inner and outer bodies until it reaches the characterized cage. Smooth changes in flow direction and no turbulences contribute to lower noise levels. The high capacity, combined with the large range ability, make our axial valve to be acknowledged as the ideal design to control over the full range of process conditions with a single valve.

As an option extended body neck is offered for cryogenic operations, with a variety

of sealing wafer. Zero emission is guaranteed by the O-ring seals combined with back- up packing. Distance between flanges is in accordance with ISA 75.03 when data are available or API 6D for larger sizes. All types of quarter turn actuator are easily mounted. Our model RAX Cv features:

Fluid is channeled into an annular path between the inner and outer bodies until it reaches the characterized cage. Smooth changes in flow direction and no turbulences contribute to lower noise levels. The high capacity, combined with the large range ability, make our axial valve to be acknowledged as the ideal design to control over the full range of process conditions with a single valve.

As an option extended body neck is offered for cryogenic operations, with a variety

of sealing wafer. Zero emission is guaranteed by the O-ring seals combined with back- up packing. Distance between flanges is in accordance with ISA 75.03 when data are available or API 6D for larger sizes. All types of quarter turn actuator are easily mounted. Our model RAX Cv features:

Actuators

Actuators assembled with Ringo valves for the HIPPS systems can be pneumatic or hydraulic and they are supply in full compliance with customer specifications. Actuators include the control panel as specified, with solenoid valves. Partial Stroke Test is available depend on SIL classification requirements.

Fluid is channeled into an annular path between the inner and outer bodies until it reaches the characterized cage. Smooth changes in flow direction and no turbulences contribute to lower noise levels. The high capacity, combined with the large range ability, make our axial valve to be acknowledged as the ideal design to control over the full range of process conditions with a single valve.

As an option extended body neck is offered for cryogenic operations, with a variety

of sealing wafer. Zero emission is guaranteed by the O-ring seals combined with back- up packing. Distance between flanges is in accordance with ISA 75.03 when data are available or API 6D for larger sizes. All types of quarter turn actuator are easily mounted. Our model RAX Cv features:

Fluid is channeled into an annular path between the inner and outer bodies until it reaches the characterized cage. Smooth changes in flow direction and no turbulences contribute to lower noise levels. The high capacity, combined with the large range ability, make our axial valve to be acknowledged as the ideal design to control over the full range of process conditions with a single valve.

As an option extended body neck is offered for cryogenic operations, with a variety

of sealing wafer. Zero emission is guaranteed by the O-ring seals combined with back- up packing. Distance between flanges is in accordance with ISA 75.03 when data are available or API 6D for larger sizes. All types of quarter turn actuator are easily mounted. Our model RAX Cv features:

- Larger Cv value, combined with high rangeability.

- Standard at 90° reduced torque actuator.

- No backlash, low friction drive mechanism, with reduced torque requirements.

- Zero stem leakage.

- Cage guided balanced plug for smooth operation.

- Linear, equal percent or other characteristics.

- Effective noise reduction and cavitation.

- Soft seated, bubble tight shut-off.

- Variety of cage designs to handle gas and liquid critical applications.

Actuators

Actuators assembled with Ringo valves for the HIPPS systems can be pneumatic or hydraulic and they are supply in full compliance with customer specifications. Actuators include the control panel as specified, with solenoid valves. Partial Stroke Test is available depend on SIL classification requirements.

Actuators

Actuators

RlNGO VALVULAS valves can be operated by any type of actuators, at customer request. When pneumatic actuators are requested we used our well proved, stiff and versatile RV models. Our scoped of supply of these kinds of actuators are divided in two different branches:- DlAPHRAGM ACTUATORS

- PlSTON ACTUATORS

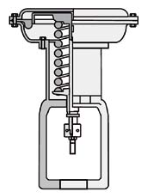

Diaphragm Actuators

Special designs are available when seismic conditions are speci ed, to increase stiffness and natural frequency. Standard materials are WCB cast steel yoke, stamped steel for cover and base plates, reinforced Buna, Neoprene, EPDM, etc., diaphragm. All parts are protected against rust and corrosion. Any type of accessories such as positioners, converters, air-sets, solenoid valves, limit switches and others as well hand wheel are tted as necessary. We use positioners and accessories from all mayor manufacturers providing the latest technology for smart instrumentation with diagnostic capabilities as well as partial stroke testing.

DIRECT ACTING

REVERSE ACTING

SIDE MOUNTED HAND WHEEL

TOP MOUNTED HAND WHEEL

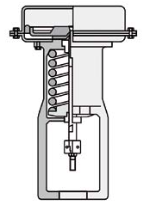

PISTON ACTUATORS

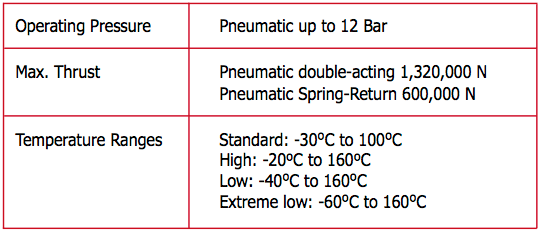

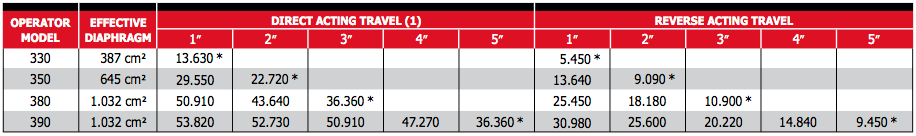

RlNGO VALVULAS manufactures a comprehensive range of double-acting and spring-return piston pneumatic actuators which suit all valve sizes. The sizing of these units is speci cally calculated for each application.

RlNGO VALVULAS manufactures a comprehensive range of double-acting and spring-return piston pneumatic actuators which suit all valve sizes. The sizing of these units is speci cally calculated for each application.

RlNGO VALVULAS manufactures a comprehensive range of double-acting and spring-return piston pneumatic actuators which suit all valve sizes. The sizing of these units is speci cally calculated for each application.